Introduction to Steel Bending Machines

Steel bending machines are powerful tools that have revolutionized metal fabrication projects. These machines are designed to bend various types of metals, including steel, into different shapes and forms. With their precise bending capabilities, they allow fabricators to create complex and intricate designs with ease. Whether you are working on a small-scale project or a large industrial one, steel bending machines can significantly enhance the efficiency and productivity of your metal fabrication processes.

Enhanced Precision and Accuracy of Steel Bending Machines

One of the key advantages of steel bending machines is their ability to provide enhanced precision and accuracy. These machines are equipped with advanced technologies, such as computer numerical control (CNC), which allows for precise control over the bending process. CNC technology ensures that each bend is executed with utmost accuracy, eliminating the risk of human error. This level of precision not only saves time but also ensures that the final product meets the desired specifications, resulting in high-quality metal fabrication projects.

Increased Efficiency and Productivity of Steel Bending Machines

Steel bending machines also offer increased efficiency and productivity in metal fabrication projects. These machines can bend metal at a much faster rate compared to manual bending methods. With their automated features and high-speed capabilities, they can handle large volumes of metal bending tasks in a fraction of the time it would take using traditional methods. As a result, fabricators can complete projects more quickly, meet tight deadlines, and take on a higher workload, ultimately increasing their overall productivity.

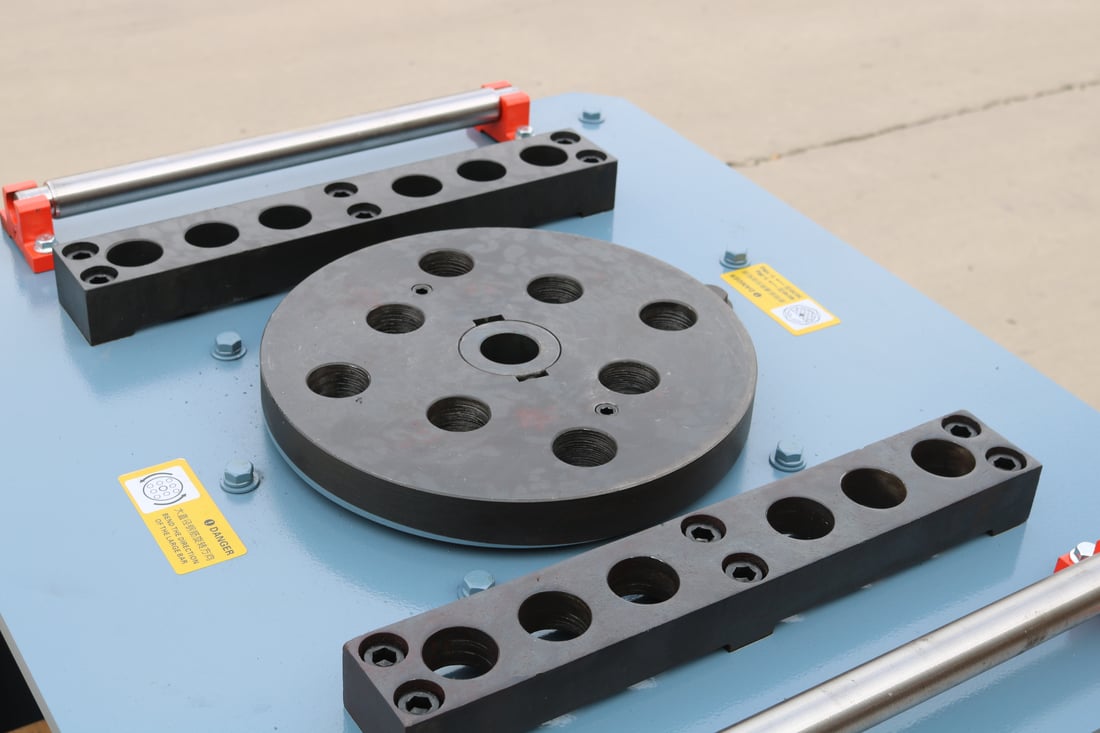

Versatile Applications of Steel Bending Machines

Another significant advantage of steel bending machines is their versatility in applications. These machines can bend a wide range of metals, including steel, aluminum, copper, and more. They can create various shapes and forms, such as curves, arcs, angles, and spirals, allowing fabricators to fulfill diverse project requirements. Whether you are in the construction industry, automotive sector, or any other field that involves metal fabrication, steel bending machines can cater to your specific needs and ensure precise and accurate bends every time.

Cost-Effective Solution of Steel Bending Machines

Investing in steel bending machines can prove to be a cost-effective solution in the long run. While the initial investment may seem significant, the efficiency and productivity gains offered by these machines can lead to substantial cost savings over time. By reducing labor costs, minimizing material waste, and increasing production output, fabricators can optimize their operations and improve their bottom line. Moreover, the high-quality bends achieved by steel bending machines result in fewer errors and reworks, further reducing costs associated with rectifying mistakes.

Conclusion

In conclusion, steel bending machines have the power to revolutionize metal fabrication projects. With their enhanced precision, increased efficiency, versatile applications, and cost-effectiveness, these machines offer numerous benefits to fabricators across various industries. By incorporating steel bending machines into your workflow, you can streamline your metal fabrication processes, improve the quality of your products, and ultimately take your projects to new heights. Embrace the power of steel bending machines and witness the transformation they bring to your metal fabrication endeavors.