The Basics of Fly Cutting in Fiber Laser Machines

Fiber laser machines have become increasingly popular in various industries for their precision and efficiency in cutting materials. One of the techniques used in fiber laser machines is fly cutting, which offers several advantages in terms of speed and accuracy. In this article, we will explore what fly cutting is, how it works, and its applications in the realm of fiber laser machines.

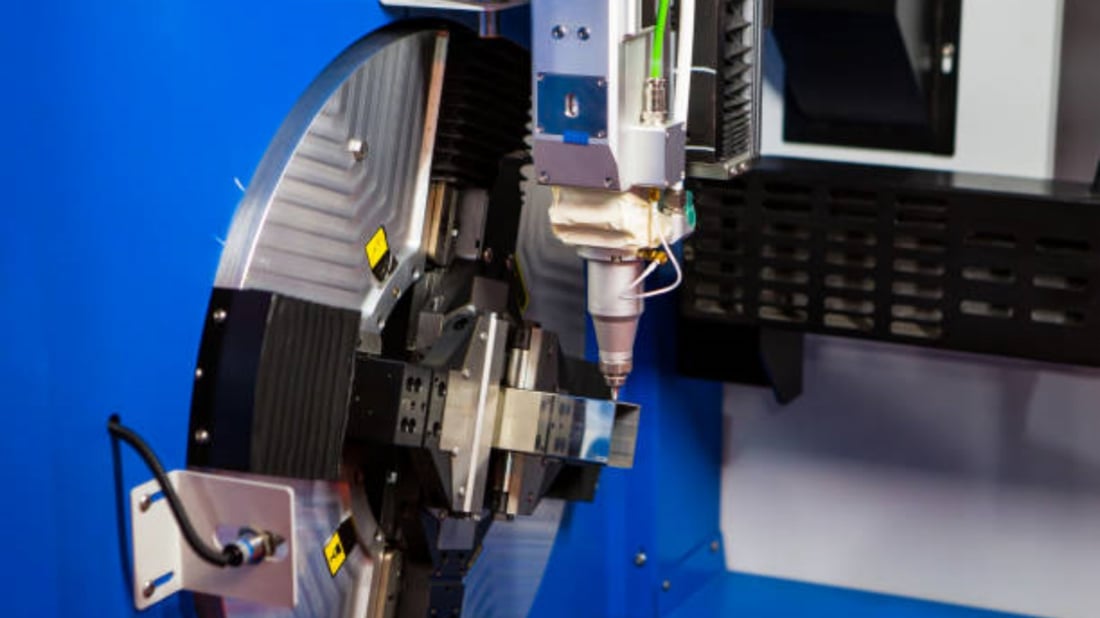

Understanding Fly Cutting in Fiber Laser Machines

Fly cutting is a machining technique that involves cutting a material with a laser beam while the material is in motion. Unlike traditional cutting methods where the material is stationary, fly cutting allows for continuous movement of the material during the cutting process. This technique is especially useful when working with large sheets or long materials.

How Does Fly Cutting Work in Fiber Laser Machines?

In fiber laser machines, fly cutting is achieved by synchronizing the motion of the material with the movement of the laser beam. The laser beam follows a predetermined path, often guided by computer numerical control (CNC) software. As the material moves beneath the laser beam, the laser cuts through the material to create the desired shape or pattern.

The Advantages of Fly Cutting in Fiber Laser Machines

Fly cutting offers several advantages over traditional cutting methods. Firstly, it allows for significantly faster cutting speeds, as the material is continuously moving. This can greatly increase productivity, especially when working on large projects or high-volume production runs. Additionally, fly cutting reduces the risk of heat buildup in the material, as the laser has less time to transfer heat to the surrounding areas.

Applications of Fly Cutting in Fiber Laser Machines

Fly cutting is widely used in various industries for different applications. One common application is in the manufacturing of metal components, such as automotive parts or aerospace components. The speed and accuracy of fly cutting make it an ideal choice for creating complex shapes and intricate designs.

Fly Cutting vs. Other Cutting Techniques

When compared to other cutting techniques, fly cutting has its own unique advantages. For example, compared to traditional punching or milling, fly cutting produces cleaner edges and reduces the need for secondary finishing operations. It also eliminates the risk of tool wear and breakage, as there is no physical contact between the cutting tool and the material.

Factors to Consider for Successful Fly Cutting

While fly cutting can offer many benefits, there are certain factors that need to be considered for successful implementation. The speed and acceleration of the material must be carefully controlled to ensure precise cutting. Optimal laser power and focus are also essential to achieve clean and accurate cuts. Additionally, the type and thickness of the material being cut should be taken into account, as different materials may require adjustments in cutting parameters.

Training and Skill Requirements

To effectively utilize fly cutting in fiber laser machines, operators require proper training and skill. Understanding the principles of laser cutting, material characteristics, and programming techniques are essential for achieving optimal results. Ongoing training and staying updated with the latest advancements in fiber laser technology can further enhance the efficiency and capabilities of fly cutting.

The Future of Fly Cutting in Fiber Laser Machines

As fiber laser technology continues to advance, fly cutting is expected to play an even more significant role in the realm of laser cutting. The ability to cut materials at high speeds with precision offers immense potential for various industries. Further improvements in laser power, control systems, and automation are likely to enhance the capabilities and versatility of fly cutting in fiber laser machines.

Conclusion

Fly cutting in fiber laser machines is a machining technique that enables cutting while the material is in motion. It offers advantages such as increased cutting speed, reduced heat buildup, and cleaner edges. Fly cutting finds applications in various industries and is especially useful for creating complex shapes and designs. With proper training and skill, operators can harness the full potential of fly cutting in fiber laser machines, further advancing the capabilities of laser cutting technology.