Chapter 1: Understanding the Basics of winder paper machines

Winder paper machines play a crucial role in the paper manufacturing process. Whether you are a paper industry professional or simply curious about how paper is made, it's essential to understand the workings of these machines. In this article, we will explore the various aspects of winder paper machines and their significance in the industry.

The Purpose of Winder Paper Machines

Winder paper machines are used to wind large rolls of paper to the desired size and tension. They are responsible for transforming the continuous web of paper produced during the manufacturing process into manageable rolls that can be easily transported, stored, and further processed.

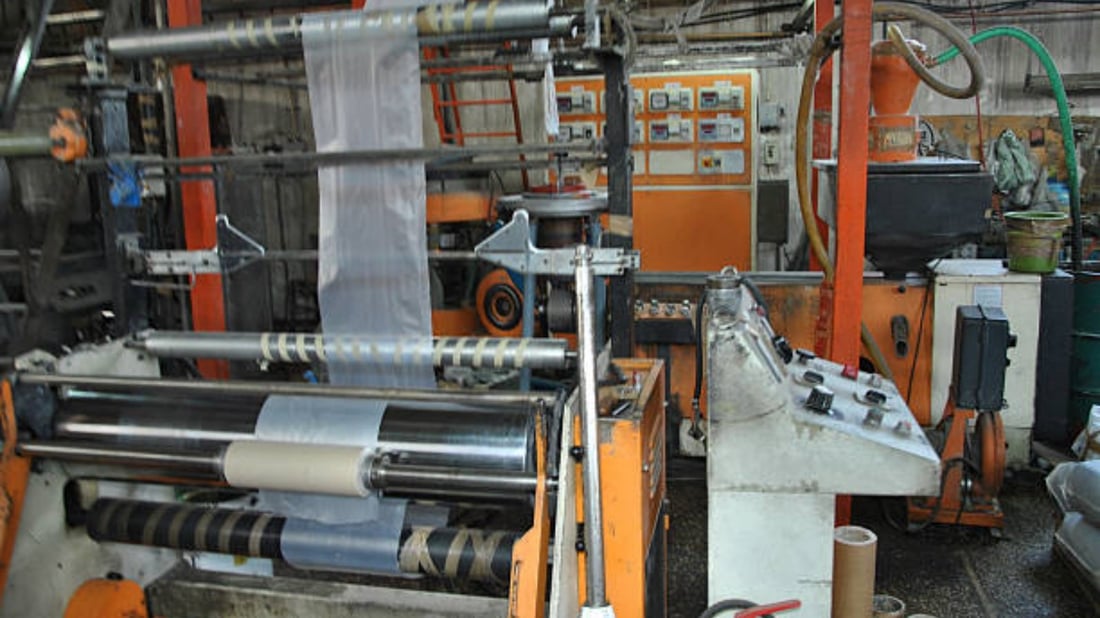

The Components of a Winder Paper Machine

A typical winder paper machine consists of several components that work together to ensure the efficient winding of paper. These components include the unwind stand, slitters, winding drum, tension control system, and the drive system. Each component plays a crucial role in achieving the desired winding quality and productivity.

Chapter 2: Types of Winder Paper Machines

1. Center Winding Machines

Center winding machines are widely used in the paper industry. They wind the paper roll from the core, ensuring even tension throughout the roll. This type of winder paper machine is ideal for applications where consistent tension is critical, such as printing and converting processes.

2. Surface Winding Machines

Surface winding machines wind the paper roll from the outside, creating a roll with varying tension across its width. This type of machine is commonly used for applications where tension variation is acceptable, such as tissue paper manufacturing.

Chapter 3: Key Considerations in Winder Paper Machine Selection

1. Speed and Productivity

When selecting a winder paper machine, it is crucial to consider the desired speed and productivity. Higher speeds and productivity levels require machines with advanced features and robust construction to handle the increased demands.

2. Winding Quality

Winding quality is another critical factor to consider. Poorly wound rolls can lead to various issues, including paper breaks, web distortions, and reduced product quality. Look for machines that offer precise tension control, slitting accuracy, and reliable winding mechanisms.

Chapter 4: Maintenance and Troubleshooting of Winder Paper Machines

1. Regular Maintenance

To ensure the optimal performance and longevity of your winder paper machine, regular maintenance is essential. This includes routine inspections, lubrication, cleaning, and replacement of worn-out parts. Following the manufacturer's maintenance guidelines is crucial to avoid unexpected breakdowns.

2. Troubleshooting Common Issues

Despite regular maintenance, winder paper machines may encounter occasional issues. Some common problems include web breaks, wrinkling, misalignment, and uneven winding. Troubleshooting these issues may involve adjusting tension settings, inspecting slitting blades, or realigning components.