Introduction

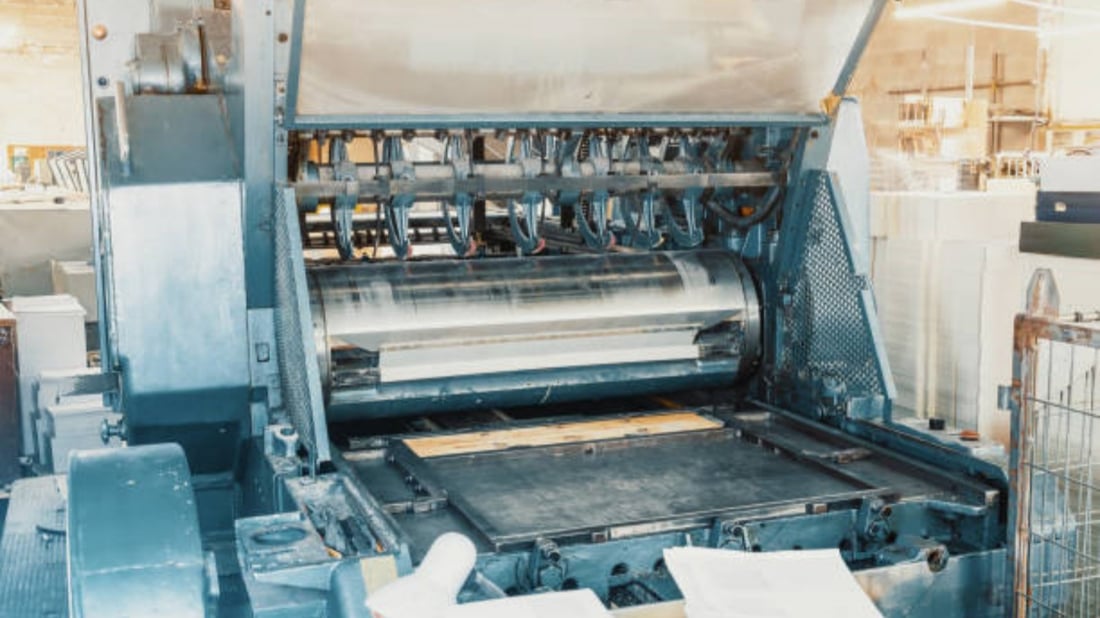

paper roll rewinding machines play a crucial role in various industries, such as printing, packaging, and paper manufacturing. These machines are designed to efficiently rewind and control the tension of paper rolls, ensuring smooth and precise rewinding. In this comprehensive guide, we will delve into the various aspects of paper roll rewinding machines, including their working principles, types, benefits, maintenance, and more. So, let's explore the world of paper roll rewinding machines.

1. Understanding the Working Principles of Paper Roll Rewinding Machines

Before we dive deeper into the details, let's first understand how paper roll rewinding machines work. These machines generally consist of a series of rollers, blades, and tension control systems. The paper roll is placed on a shaft, which is then mounted onto the machine's structure. As the machine starts, the paper roll unwinds, passes through the tension control system, and then rewinds onto a new core. The tension control system ensures the paper is rewound evenly and without any wrinkles or creases.

2. Different Types of Paper Roll Rewinding Machines

Paper roll rewinding machines come in various types, each designed for specific applications. Some common types include:

2.1 Manual Paper Roll Rewinding Machines

These machines require manual intervention to operate. They are suitable for small-scale operations or when the rewinding process requires human supervision.

2.2 Semi-Automatic Paper Roll Rewinding Machines

With semi-automatic machines, the rewinding process is partially automated. Operators need to input some settings and monitor the process, but the machine takes care of most of the rewinding tasks.

2.3 Fully Automatic Paper Roll Rewinding Machines

These state-of-the-art machines offer complete automation. They are capable of handling large volumes of paper rolls without much human intervention. The settings can be programmed, and the machine takes care of the entire rewinding process.

3. Benefits of Using Paper Roll Rewinding Machines

Investing in a paper roll rewinding machine can bring numerous benefits to your business. Some key advantages include:

3.1 Increased Efficiency and Productivity

By automating the rewinding process, these machines significantly improve efficiency and productivity. They can handle large rolls of paper quickly and accurately, reducing downtime and increasing output.

3.2 Enhanced Quality Control

Paper roll rewinding machines ensure precise tension control, resulting in high-quality rewound rolls. This helps eliminate wrinkles, creases, and other defects that can affect the end product's quality.

3.3 Cost Savings

Using paper roll rewinding machines can lead to cost savings in the long run. They minimize paper wastage, reduce labor costs, and increase overall operational efficiency.

4. Factors to Consider When Choosing a Paper Roll Rewinding Machine

When selecting a paper roll rewinding machine, it's important to consider various factors to ensure the machine meets your specific requirements. Some key factors to consider include:

4.1 Maximum Roll Diameter and Width

Different machines have varying capacities in terms of roll diameter and width. It's crucial to choose a machine that can handle the size of paper rolls you typically work with.

4.2 Speed and Production Capacity

The speed and production capacity of the machine determine how quickly it can rewind paper rolls. Consider your production requirements and choose a machine that aligns with your desired output.

4.3 Control System and Features

Modern paper roll rewinding machines come with advanced control systems and features. These include programmable settings, tension control mechanisms, and error detection. Assess the available features to ensure they meet your specific needs.

5. Proper Maintenance and Care

Maintaining your paper roll rewinding machine is essential to ensure its longevity and optimal performance. Here are some maintenance tips:

5.1 Regular Cleaning

Keep the machine clean by removing dust, debris, and residual paper particles. This helps prevent jamming and ensures smooth operation.

5.2 Lubrication

Apply lubricants to the moving parts of the machine to reduce friction and enhance its overall performance. Follow the manufacturer's guidelines for the appropriate lubrication schedule.

5.3 Routine Inspections

Regularly inspect the machine for any signs of wear and tear. Replace any damaged or worn-out parts promptly to prevent further damage and maintain the machine's efficiency.

6. Safety Considerations

When working with paper roll rewinding machines, it's crucial to prioritize safety. Here are some safety considerations:

6.1 Operator Training

Ensure operators receive proper training on how to operate the machine safely and efficiently. This includes understanding emergency procedures and using personal protective equipment.

6.2 Machine Guards

Install appropriate machine guards to protect operators from potential hazards, such as rotating parts and blades. Regularly inspect and maintain these guards to ensure their effectiveness.

6.3 Safety Signs and Labels

Place clear and visible safety signs and labels near the machine to remind operators of potential risks and safety precautions. This helps create a safer working environment.

7. Common Challenges and Troubleshooting

While paper roll rewinding machines are reliable, they can encounter occasional challenges. Here are some common issues and possible troubleshooting steps:

7.1 Paper Jamming

If the machine experiences frequent paper jams, check for any obstructions or misalignment in the paper path. Clear the jammed paper and ensure the rolls are properly aligned.

7.2 Wrinkled or Uneven Rewinding

Inconsistent tension or improper alignment can lead to wrinkled or uneven rewinding. Check the tension control system and adjust it accordingly. Also, ensure the rolls are correctly positioned on the shaft.

7.3 Blade Dullness

Dull blades can result in poor cutting performance. Regularly inspect the blades and sharpen or replace them as needed to ensure clean and precise cuts.

8. Industry Applications of Paper Roll Rewinding Machines

Paper roll rewinding machines find applications in various industries. Some common industries that benefit from these machines include:

8.1 Printing and Publishing

Printing companies rely on paper roll rewinding machines to efficiently rewind large rolls of paper used in printing presses. This ensures a continuous supply of paper without interruptions.

8.2 Packaging

Packaging companies use paper roll rewinding machines to produce rolls of packaging material. These rolls are then used in various packaging processes, such as wrapping, cushioning, and labeling.

8.3 Paper Manufacturing

In the paper manufacturing industry, paper roll rewinding machines play a vital role in rewinding large parent rolls into smaller rolls for further processing or distribution.

9. Future Trends and Innovations

The field of paper roll rewinding machines continues to evolve, driven by technological advancements and market demands. Some future trends and innovations to watch out for include:

9.1 Automation and Integration

Further automation and integration of paper roll rewinding machines with other manufacturing processes are expected. This will streamline operations and enhance overall efficiency.

9.2 Eco-Friendly Solutions

Manufacturers are increasingly focusing on developing eco-friendly paper roll rewinding machines. These machines will prioritize energy efficiency and reduce environmental impact.

9.3 Smart Monitoring and Maintenance

Smart technologies, such as remote monitoring and predictive maintenance, will become more prevalent. These features will enable real-time monitoring and proactive maintenance to minimize downtime.

10. Conclusion

Paper roll rewinding machines are indispensable in various industries, offering efficient and precise rewinding of paper rolls. By understanding their working principles, types, benefits, and maintenance requirements, you can make informed decisions when choosing and operating these machines. Stay updated with the latest trends and innovations in this field to optimize your production processes and stay ahead of the competition. Invest in a reliable paper roll rewinding machine, and witness the positive impact it brings to your business.