Introduction

If you work in a printing or packaging company, you probably know the importance of strong, secure bonds between papers. Without the right bonding method, papers can easily detach, ruining the appearance and functionality of your printed product. Fortunately, modern technology has given us paper bonding machines, devices designed to bond two or more sheets of paper together in a fast, efficient, and cost-effective manner. In this article, we will explore the ins and outs of paper bonding machines, including how they work, their key benefits, and how to choose the right one for your needs.

What is a Paper Bonding Machine?

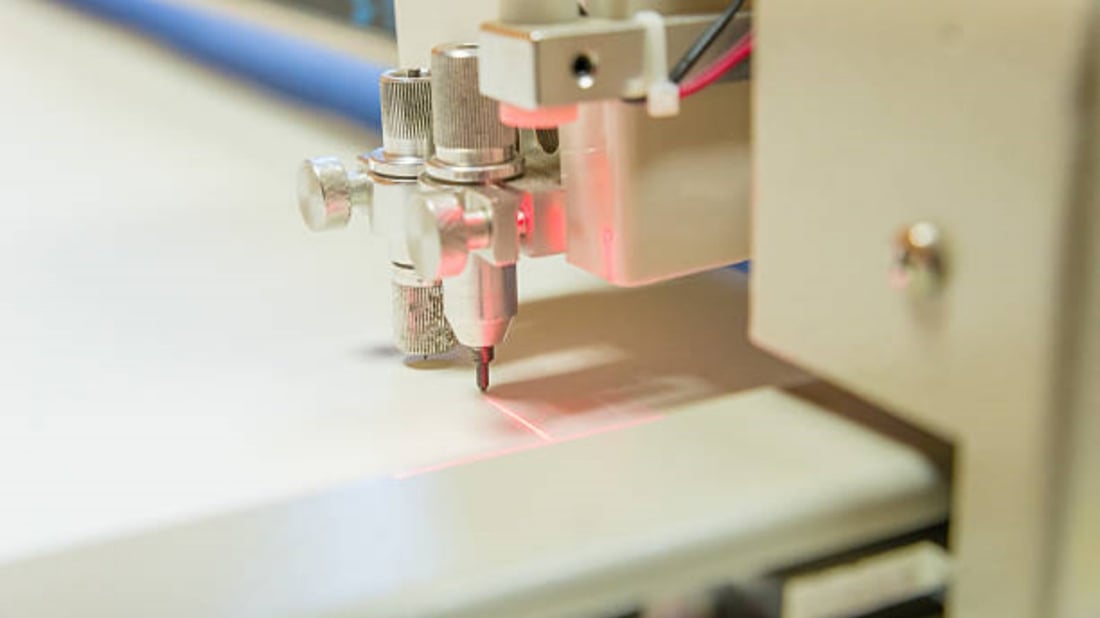

A paper bonding machine is a specialized device that applies heat and pressure to two or more sheets of paper, causing them to bond together at the molecular level. The bonding can be achieved through a variety of methods, including thermal bonding, pressure bonding, and ultrasonic bonding.

How Does a Paper Bonding Machine Work?

The exact process of paper bonding depends on the type of machine and bonding method used. In general, however, the process involves placing two or more sheets of paper between two heated rollers or plates. The pressure and heat cause the fibers of the paper to mesh together, forming a strong bond that will not come apart easily.

Key Benefits of a Paper Bonding Machine

There are many benefits to using a paper bonding machine, including:

- Increased strength and durability of the finished product

- Improved appearance, as there are no visible seams or creases

- Increased efficiency and productivity, as bonding can be done quickly and easily

- Reduced waste, as there is no need for adhesives or stitching

- Cost-effectiveness, as bonding is a relatively inexpensive process

Types of Paper Bonding Machines

There are several types of paper bonding machines available on the market, each with its own advantages and disadvantages:

- Thermal bonding machines: These machines use heat and pressure to bond paper together, and are ideal for larger sheets of paper.

- Ultrasonic bonding machines: These machines use high-frequency vibrations to bond paper together, and are ideal for small or delicate sheets of paper.

- Pressure bonding machines: These machines use pressure to bond paper together, and are ideal for thicker stock.

Factors to Consider When Choosing a Paper Bonding Machine

When choosing a paper bonding machine, there are several factors to consider:

- Size and capacity: Choose a machine that can accommodate the size and thickness of the paper you will be bonding.

- Bonding method: Choose a machine that uses the bonding method best suited for your needs.

- Speed and efficiency: Choose a machine that can bond papers quickly and efficiently, without sacrificing quality.

- Cost: Choose a machine that fits within your budget, and consider the long-term cost savings of using a paper bonding machine.

- Brand and reputation: Choose a machine from a reputable brand with a proven track record of quality and reliability.

How to Use a Paper Bonding Machine

Using a paper bonding machine is relatively straightforward:

- Prepare the paper to be bonded by trimming it to the desired size and shape.

- Insert the paper between the rollers or plates of the bonding machine.

- Adjust the temperature and pressure settings according to the bonding method and type of paper being used.

- Activate the machine, and allow it to bond the papers together for the specified amount of time.

- Remove the bonded papers from the machine, and repeat the process as needed.

Common Applications of Paper Bonding Machines

Paper bonding machines can be used in a wide range of applications, including:

- Bookbinding

- Packaging

- Product labeling

- Printing

- Decorative paper crafts

Conclusion

Whether you work in printing, packaging, or any other industry that requires secure paper bonds, a paper bonding machine can be an invaluable tool. By understanding the different types and factors to consider when choosing a machine, as well as its many benefits and applications, you can select the right machine to meet your specific needs and achieve optimal results.