Introduction

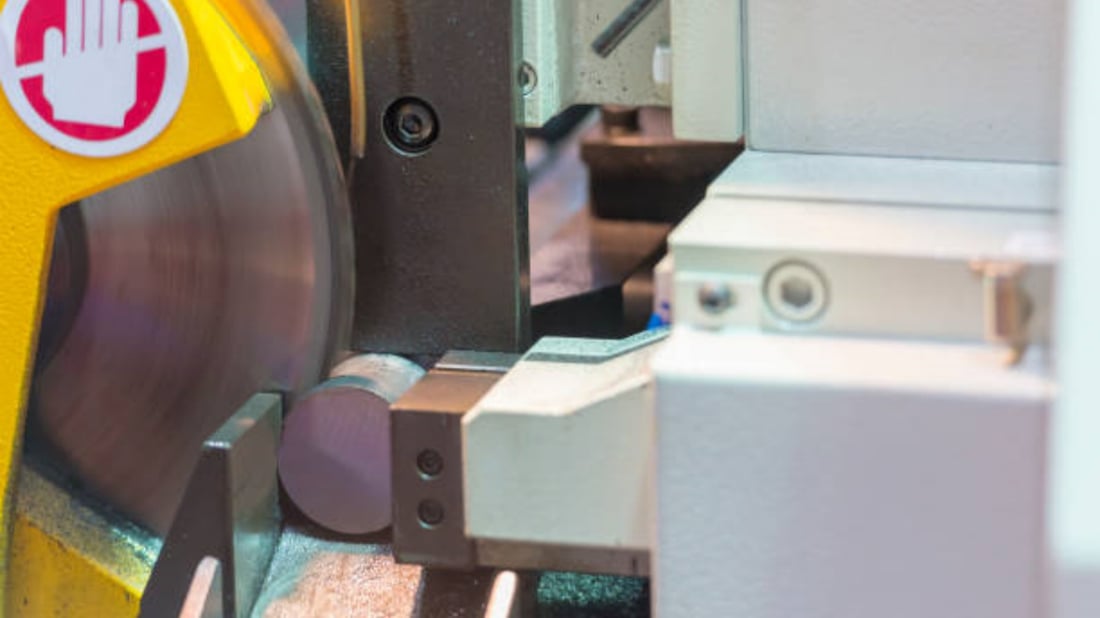

industrial process equipment plays a crucial role in modern manufacturing processes. It encompasses a wide range of machinery, tools, and systems that facilitate various stages of production, ensuring efficiency, accuracy, and productivity. In this article, we will explore the different aspects of industrial process equipment and its significance in the manufacturing industry.

The Evolution of Industrial Process Equipment

Over the years, industrial process equipment has undergone significant advancements, driven by technological innovations and the need for automation. From traditional manual tools to sophisticated computer-controlled systems, the evolution of industrial process equipment has revolutionized manufacturing processes. Today, industries heavily rely on advanced machinery to streamline production, reduce costs, and enhance product quality.

Types of Industrial Process Equipment

There is a vast array of industrial process equipment available, each designed to fulfill specific functions in the manufacturing process. Some common types include:

- 1. Conveyors: These systems transport materials or products between different stages of production, ensuring a smooth flow.

- 2. Mixers and Blenders: Used for combining raw materials or substances to create homogeneous mixtures.

- 3. Heat Exchangers: These devices facilitate the transfer of heat between fluids, allowing for temperature control during various processes.

- 4. Separators: Used to separate solid particles from liquid or gas streams, ensuring purification and quality control.

- 5. Pumps: Essential for moving fluids through pipelines or containers, facilitating the transfer of materials.

- 6. Compressors: These machines increase the pressure of a gas, making it easier to transport or store.

- 7. Valves: Control the flow of fluids or gases, enabling precise regulation and preventing leaks.

- 8. Dryers: Remove moisture from materials or products, enhancing their stability and shelf life.

The Significance of Industrial Process Equipment

Industrial process equipment plays a vital role in manufacturing for several reasons:

1. Increased Efficiency

By automating processes and reducing manual labor, industrial process equipment significantly improves efficiency. Machinery can perform tasks at higher speeds, with greater precision and accuracy than humans, resulting in increased productivity and reduced cycle times.

2. Enhanced Product Quality

Industrial process equipment helps maintain consistent product quality by eliminating human errors and variations. Automated systems ensure that manufacturing parameters are precisely controlled, resulting in uniform products that meet or exceed industry standards.

3. Cost Reduction

Investing in industrial process equipment can lead to long-term cost savings. By streamlining processes, reducing waste, and minimizing resource consumption, manufacturers can achieve higher production yields and lower operational costs. Additionally, automation reduces the reliance on manual labor, further decreasing expenses associated with workforce management.

4. Improved Safety

Industrial process equipment often incorporates safety features that protect workers from potential hazards. Automated systems can perform tasks that may be dangerous or physically demanding, reducing the risk of accidents and injuries. This leads to a safer working environment and promotes employee well-being.

5. Scalability and Adaptability

Industrial process equipment is designed to be scalable and adaptable to changing production requirements. Manufacturers can easily modify or upgrade their equipment to accommodate increased production volumes or introduce new products. This flexibility allows businesses to stay competitive in a dynamic market.

6. Compliance with Regulations

Many industries operate under strict regulations and standards. Industrial process equipment often includes built-in features that ensure compliance with these requirements. By using equipment designed to meet industry-specific regulations, manufacturers can avoid penalties, maintain their reputation, and ensure customer satisfaction.

7. Data Collection and Analysis

Advanced industrial process equipment often incorporates data collection and analysis capabilities. This allows manufacturers to gather valuable insights into their processes, identify areas for improvement, and make data-driven decisions. By leveraging this data, companies can optimize their operations, reduce waste, and enhance overall efficiency.

8. Environmental Sustainability

Industrial process equipment can contribute to environmental sustainability efforts. By optimizing resource usage, reducing emissions, and implementing energy-efficient technologies, manufacturers can minimize their ecological footprint. This not only benefits the environment but also aligns with evolving consumer preferences for sustainable products and responsible manufacturing.

Conclusion

Industrial process equipment is the backbone of modern manufacturing. Its continuous evolution and integration of advanced technologies have revolutionized production processes, enabling higher efficiency, improved product quality, and cost reduction. With the ever-growing demand for faster and more sustainable manufacturing, investing in the right industrial process equipment is crucial for businesses aiming to stay competitive in today's market.