Introduction

coil processing equipment plays a crucial role in the manufacturing industry, particularly in metal fabrication and processing. This equipment is essential for efficiently transforming raw coils of material into usable products for various applications. From cutting and slitting to leveling and recoiling, coil processing equipment ensures the smooth and precise handling of materials. In this article, we will explore the different aspects and benefits of coil processing equipment and how it contributes to the success of manufacturing operations.

The Basics of Coil Processing Equipment

Coil processing equipment refers to a range of machinery used in the processing and manipulation of coiled materials, such as metal coils. These coils are typically unwound, processed, and rewound to achieve desired specifications. The equipment involved in this process includes coil slitters, cut-to-length lines, levelers, recoilers, and more. Each machine serves a specific purpose and is designed to deliver consistent and high-quality results.

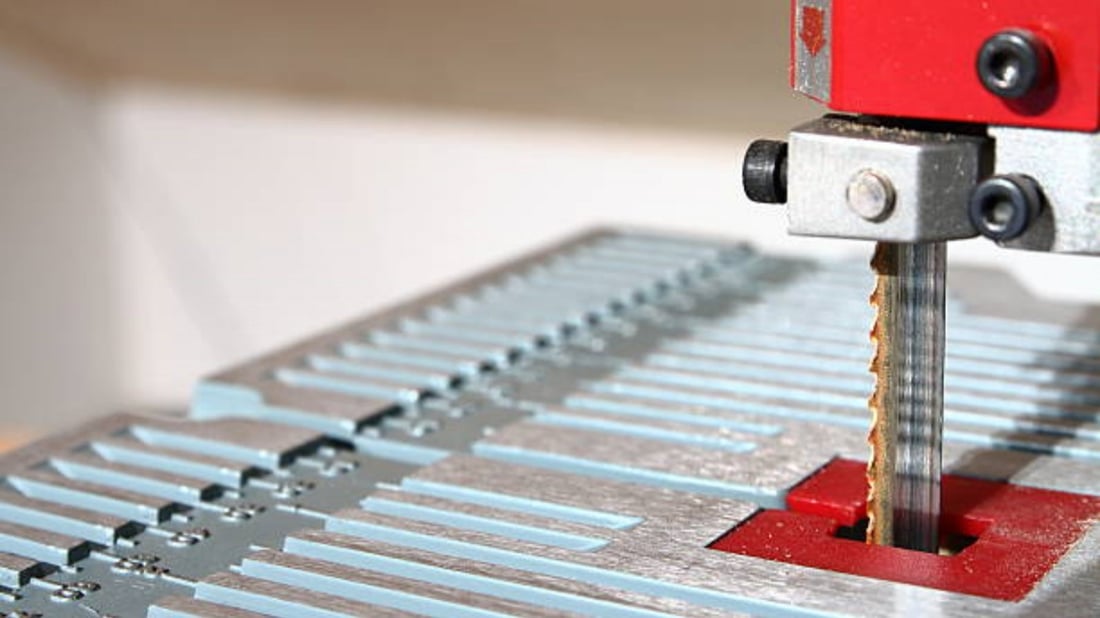

Efficient Coil Slitting for Precision Cuts

Coil slitting is a critical step in coil processing that involves cutting wide coils into narrower strips. This process is commonly used in industries such as automotive, construction, and appliance manufacturing. Coil slitting machines are equipped with multiple circular blades that can slit the coil into various widths, allowing for greater flexibility in product customization. With precise blade control and advanced automation, coil slitting equipment ensures accurate and efficient cutting, resulting in high-quality finished products.

Precision Cut-to-Length Lines for Customization

Another important aspect of coil processing equipment is the cut-to-length lines. These machines are designed to cut coils into specific lengths, providing manufacturers with customized materials tailored to their requirements. Cut-to-length lines utilize advanced technology, such as servo-driven feed systems and programmable logic controllers (PLCs), to ensure precise cutting accuracy and increased productivity. With the ability to handle various materials and thicknesses, cut-to-length lines offer versatility and efficiency in material processing.

Enhancing Material Flatness and Quality with Levelers

Coil levelers are essential equipment in coil processing, especially when dealing with materials that need to be flattened before further processing. Levelers use a series of rolls to remove or reduce the shape imperfections, such as coil set and crossbow, that occur during the coiling process. By applying pressure and tension to the material, levelers can improve flatness and eliminate stress, resulting in higher-quality end products. Advanced levelers incorporate features like automatic thickness adjustment and feedback control systems to ensure consistent material flatness and meet tight tolerance requirements.

Recoiling for Efficient Handling and Storage

After the processing and customization of coils, recoiling equipment is used to rewind the material into compact and manageable coils. Recoiling machines are equipped with advanced winding mechanisms that ensure tight and uniform winding, preventing material damage and facilitating easier transportation and storage. With features like automatic tension control and programmable settings, recoilers offer excellent control over the winding process, resulting in consistent coil quality and improved overall efficiency.

The Benefits of Coil Processing Equipment

Coil processing equipment offers numerous benefits to manufacturers in various industries. Firstly, it enables efficient material utilization by reducing waste and optimizing production output. By precisely cutting and customizing coils, manufacturers can minimize scrap and maximize material usage, leading to cost savings and improved profitability. Additionally, coil processing equipment enhances product quality and consistency by ensuring accurate dimensions, flatness, and surface finish. This translates to higher customer satisfaction and increased market competitiveness.

Increased Productivity and Reduced Labor Costs

With the automation and advanced technology integrated into coil processing equipment, manufacturers can significantly increase their productivity while reducing labor costs. Automated coil processing lines can handle large volumes of material with minimal human intervention, resulting in faster processing times and improved overall efficiency. By minimizing manual labor requirements, manufacturers can allocate resources to more value-added tasks and achieve higher productivity levels.

Improved Workplace Safety and Operator Well-being

Coil processing equipment also contributes to a safer and healthier workplace environment. By automating repetitive and physically demanding tasks, it reduces the risk of accidents and injuries associated with manual material handling. Additionally, advanced safety features, such as guards, sensors, and emergency stop systems, ensure operator safety during machine operation. The implementation of coil processing equipment not only enhances workplace safety but also promotes the well-being and job satisfaction of operators.

Enhanced Customization Capabilities

Coil processing equipment enables manufacturers to offer a wide range of customized products to meet specific customer requirements. With the ability to cut coils into various widths and lengths, as well as control material flatness and surface finish, manufacturers can deliver tailored solutions that cater to diverse applications. This flexibility in customization enhances customer satisfaction and opens doors to new market opportunities for manufacturers.

The Future of Coil Processing Equipment

As technology continues to advance, so does the coil processing equipment. Industry 4.0 concepts, such as the Internet of Things (IoT) and artificial intelligence (AI), are being integrated into coil processing equipment to enhance automation, data collection, and predictive maintenance capabilities. These advancements will further optimize production processes, improve quality control, and increase overall efficiency. Coil processing equipment will continue to play a vital role in the manufacturing industry, enabling manufacturers to stay competitive in an ever-evolving market.