Understanding the Laser cutting thickness limit?

When it comes to laser cutting, one of the crucial factors to consider is the thickness limit of the material. Laser cutting has revolutionized the manufacturing industry, providing precision and efficiency. However, every material has its own specific thickness limit that determines whether it can be cut effectively with a laser. In this article, we will explore the laser cutting thickness limit and its importance in various industries.

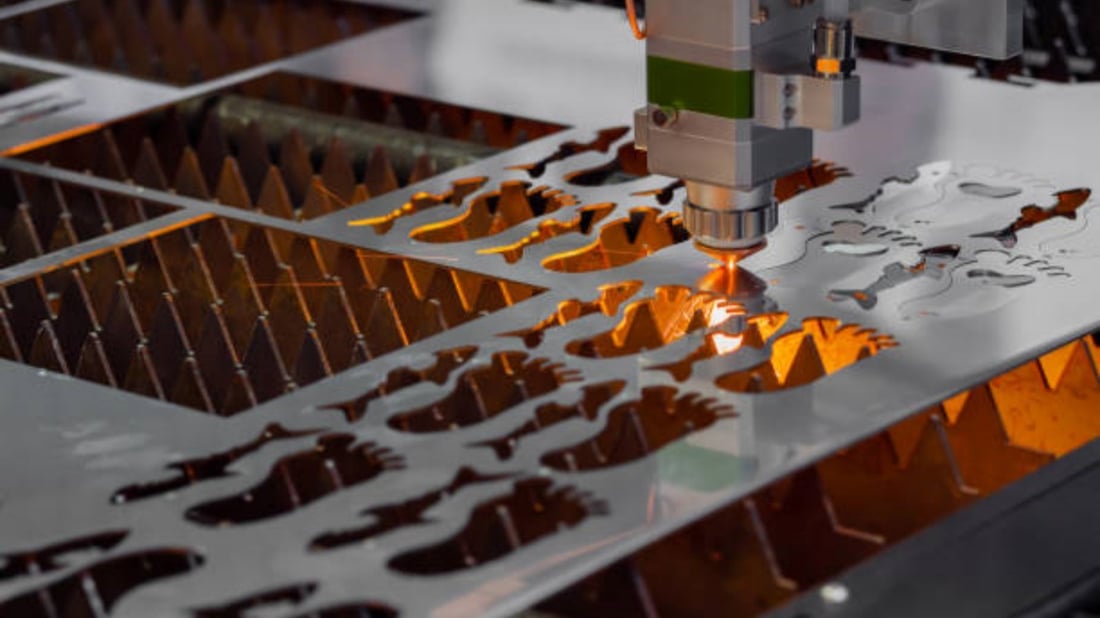

The Basics of Laser Cutting

Laser cutting is a technology that uses a high-powered laser beam to cut through different materials with extreme precision. The laser beam melts, burns, or vaporizes the material, resulting in a smooth and accurate cut. It is widely used in industries such as automotive, aerospace, electronics, and many others.

Factors Affecting Laser Cutting Thickness Limit

Several factors influence the laser cutting thickness limit, including the type of laser used, power output, material properties, and the desired quality of the cut. Let's delve deeper into each of these factors:

Type of Laser

There are various types of lasers used in laser cutting, including CO2 lasers, fiber lasers, and solid-state lasers. Each type has its own advantages and limitations. CO2 lasers are commonly used for cutting non-metallic materials, while fiber lasers are ideal for cutting metals. Solid-state lasers offer a balance between the two. The choice of laser type affects the maximum thickness that can be cut effectively.

Power Output

The power output of a laser determines its cutting capability. Higher power lasers can cut through thicker materials with ease. However, it is important to note that higher power also increases the cost of the laser system. Finding the right balance between power and budget is crucial when considering the thickness limit.

Material Properties

Every material has unique properties that affect its laser cutting thickness limit. The density, melting point, and thermal conductivity play a significant role in determining the maximum thickness that can be cut. Materials with high thermal conductivity, such as copper, require higher laser power to achieve the same cutting depth as materials with lower thermal conductivity.

Desired Cut Quality

The desired quality of the cut also influences the laser cutting thickness limit. If a clean, precise cut is required, the thickness limit might be lower compared to a rougher cut. The cutting speed and focus also impact the quality of the cut. Balancing speed, focus, and thickness limit is crucial to achieve the desired results.

Applications and Industries

Laser cutting finds applications in various industries, including:

Automotive

In the automotive industry, laser cutting is used to fabricate intricate parts, such as body panels, exhaust systems, and engine components. The laser cutting thickness limit determines the feasibility of using this technology for specific parts.

Aerospace

Aerospace industry demands high precision and quality. Laser cutting is utilized for manufacturing components like turbine blades, fuselage parts, and brackets. The thickness limit is crucial to ensure the structural integrity of these parts.

Electronics

Laser cutting is widely used in the electronics industry for cutting circuit boards, display panels, and other intricate electronic components. The laser cutting thickness limit determines the precision and accuracy of these cuts.

Architecture and Interior Design

Architects and interior designers often use laser cutting to create intricate designs in metal, wood, and acrylic. The laser cutting thickness limit determines the level of detail that can be achieved in these designs.

Conclusion

The laser cutting thickness limit plays a vital role in determining the feasibility of using laser cutting technology for different materials and applications. Factors such as the type of laser, power output, material properties, and desired cut quality all contribute to this limit. Understanding and respecting the thickness limit is crucial for achieving accurate and efficient cuts.