The Advantages of Using a cutting bending machine

When it comes to industrial manufacturing processes, precision and efficiency are key factors that can make or break a company's success. One tool that has revolutionized the industry is the cutting bending machine. This powerful device offers numerous advantages over traditional methods, allowing manufacturers to streamline their operations and produce high-quality products with ease.

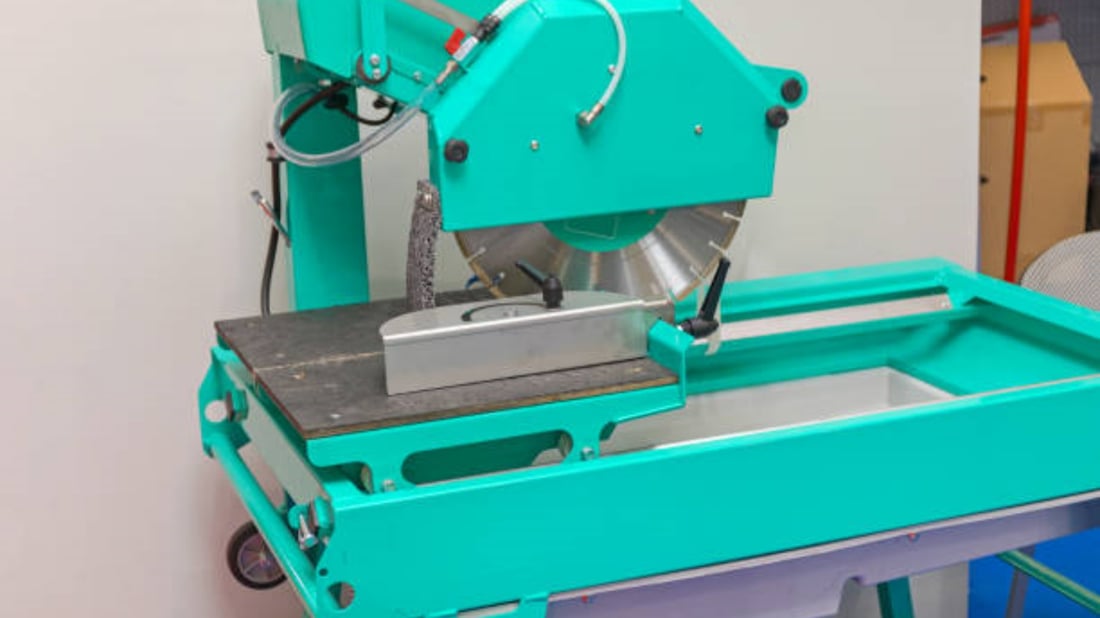

What is a Cutting Bending Machine?

A cutting bending machine is a versatile piece of equipment that combines the functions of both cutting and bending. It is commonly used in the metalworking industry to shape various materials such as steel, aluminum, and other metals. This machine employs advanced technology and automation to perform precise cuts and bends, reducing the need for manual labor and minimizing human error.

Precision Cutting for Perfect Results

One of the primary benefits of using a cutting bending machine is its ability to perform precision cuts. Traditional cutting methods often lead to uneven edges and imprecise angles, resulting in wasted materials and additional work to correct the errors. With a cutting bending machine, manufacturers can achieve perfect cuts every time, ensuring a high level of accuracy and reducing material waste.

Efficient Bending for Complex Shapes

Bending metal into complex shapes can be a challenging task that requires skill and expertise. However, with a cutting bending machine, this process becomes much more efficient and precise. The machine's advanced technology and programmable controls allow manufacturers to easily bend metal into various shapes and angles, eliminating the need for manual labor and reducing the risk of errors.

Increased Productivity and Cost Savings of Using a cutting bending machine

By incorporating a cutting bending machine into their operations, manufacturers can significantly increase their productivity levels. The machine's automation capabilities enable it to work continuously without the need for breaks, resulting in faster production times and higher output. Additionally, the reduction in manual labor leads to cost savings, as fewer workers are required to operate the machine.

Improved Safety and Worker Well-being

Working with heavy machinery can be dangerous, but cutting bending machines prioritize safety. These machines are equipped with various safety features, such as emergency stop buttons and protective barriers, to prevent accidents and injuries. By minimizing the risk of workplace accidents, manufacturers can ensure the well-being of their workers and create a safer working environment.

Versatility and Adaptability of Using a cutting bending machine

Another advantage of cutting bending machines is their versatility and adaptability. These machines can handle a wide range of materials and thicknesses, making them suitable for various industries and applications. Whether it's shaping metal sheets for construction or creating intricate designs for automotive parts, cutting bending machines can handle the task with ease.

Reduced Material Waste and Environmental Impact

Traditional cutting and bending methods often result in significant material waste, which not only increases costs but also has a negative environmental impact. Cutting bending machines minimize material waste by performing precise cuts and bends, optimizing the use of materials. This reduction in waste contributes to a more sustainable manufacturing process, making cutting bending machines an eco-friendly choice.

Improved Quality and Consistency of Using a cutting bending machine

Consistency is crucial in manufacturing, especially when it comes to producing identical parts or components. Cutting bending machines excel in delivering consistent results, ensuring that each product meets the required specifications. By eliminating human error and maintaining a high level of precision, these machines contribute to improved product quality and customer satisfaction.

The Future of Cutting Bending Machines

The cutting bending machine continues to evolve and improve, with advancements in technology and automation. Manufacturers can expect even more efficient, accurate, and user-friendly machines in the future. As the demand for precision and productivity increases, cutting bending machines will play a vital role in shaping the manufacturing industry.