Are laser welding machines any good?? A Comprehensive Guide

Welding is a process that involves joining metals to create structures used in various industries. Over the years, welding technology has evolved, and one of the latest advancements is the use of laser welding machines. But are laser welding machines any good? Let’s explore this topic in-depth.

What is a Laser Welding Machine?

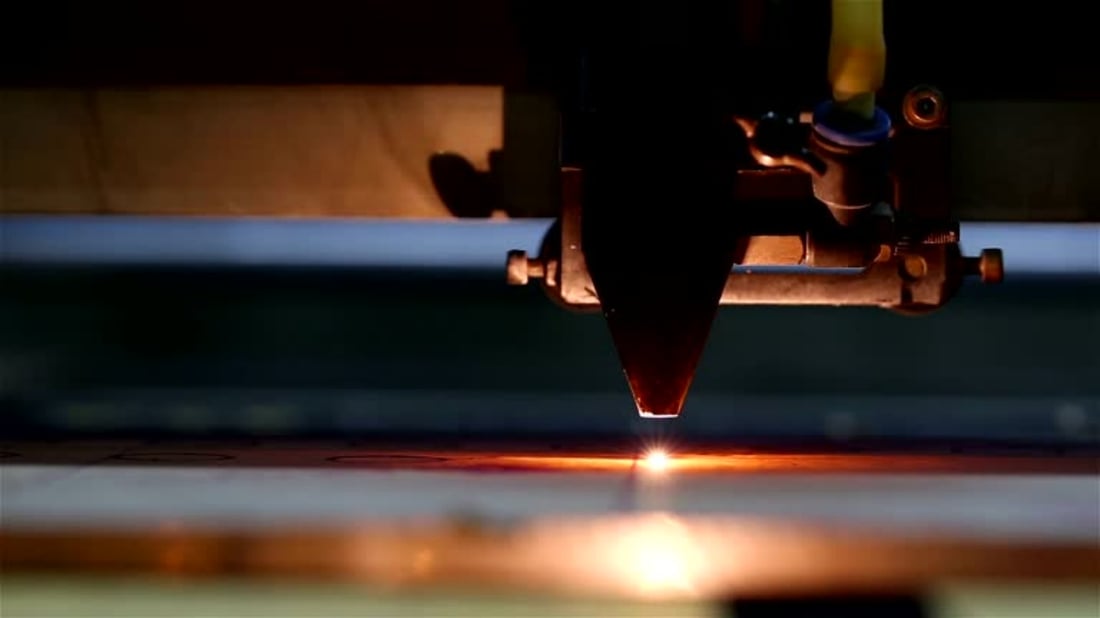

A laser welding machine is a tool that uses a laser beam to join metals together. This process occurs by focusing a concentrated beam of light on the welding area, heating the metals, and joining them at the point of contact.

How Do Laser Welding Machines Work?

Laser welding machines work by using a laser beam that is focused on the welding area. The laser beam generates heat that melts the metals and joins them together. The welding process is automated and controlled by a computer program that sets the parameters based on the metal being joined.

Advantages of Laser Welding Machines

Precision: Laser welding machines can produce highly precise welds, making them suitable for delicate objects, such as medical devices and electronic components.

Speed: Laser welding machines can join metals quickly, leading to increased productivity.

Quality: Laser welding machines produce high-quality welds, resulting in stronger and more durable finished products.

Disadvantages of Laser Welding Machines

Cost: Laser welding machines can be expensive to buy and maintain.

Complexity: Laser welding machines require trained personnel to operate, and the process can be complex.

Material Limitations: Laser welding machines may not be suitable for all types of metals and alloys.

Applications of Laser Welding Machines

Laser welding machines can have applications in various industries such as:

Automotive: Laser welding machines can be used to join different parts of a car, including body panels and exhaust systems.

Medical: Laser welding machines can join small medical devices, such as pacemakers and implantable sensors.

Electronics: Laser welding machines can join electronic components, such as printed circuit boards and LED arrays.

Factors to Consider When Choosing a Laser Welding Machine

Type of Laser: There are different types of lasers that can be used in a welding machine, including CO2, fiber, and Nd:YAG. Different lasers are suitable for specific welding applications.

Machine Power: The power of the welding machine affects the speed and quality of the welding process. Higher power machines can weld thicker metals more quickly.

Machine Price: The cost of a welding machine depends on its features and capabilities. It is essential to choose a machine that fits your budget and meets your welding needs.

Conclusion

Are laser welding machines any good? Yes, laser welding machines can produce high-quality welds quickly and with precision. However, they come with some disadvantages, such as cost and complexity. Understanding the advantages and applications of laser welding machines and knowing what to consider when choosing a machine can help you decide if a laser welding machine is right for your needs.